Highest precision microfabrication technologies

Two-Photon Polymerization (2PP), also known as two-photon or multi-photon lithography or direct laser writing, is a key enabling technology for innovations in high-precision additive manufacturing with 3D printing and grayscale lithography systems. Print any 3D design with submicron features and sizes up to the centimeter range, with excellent shape accuracy and at the highest throughput.

Additive manufacturing by 3D printing enables design freedom not only at the macroscale, but also at the nano-, micro- and mesoscale. Two-Photon Polymerization (2PP) is the key technology for achieving this, based on the principle of two-photon absorption and providing a resolution 100 times higher than 3D printing technologies based on one-photon absorption. 2PP is thus an established method for nanofabrication and microfabrication of 3D structures for microoptics, microfluidics, micromechanics and life science applications such as tissue engineering and drug delivery devices.

Pioneering 2PP-based microfabrication technologies

open up new applications and drive emerging markets

Two-Photon Polymerization technology is advancing rapidly, driven by emerging applications that inspire new technological innovations and set new standards for high-resolution 3D printing. Get an in-depth understanding of the underlying Two-Photon Polymerization technology and how it has evolved to meet specific requirements of 3D nanofabrication and microfabrication:

Two-Photon Polymerization

2PP

Two-Photon Polymerization (2PP) utilizes femtosecond laser light pulses to crosslink photopolymers for high-resolution 3D printing at the nano-, micro-, meso- and macroscale.

Two-Photon Grayscale Lithography 2GL®

Two-Photon Grayscale Lithography (2GL®) employs high-speed laser modulation for voxel tuning to print 2.5D topographies with an exceptionally high throughput and excellent shape accuracy.

Two-Photon Polymerization

is the key technology for 3D nano- and microfabrication

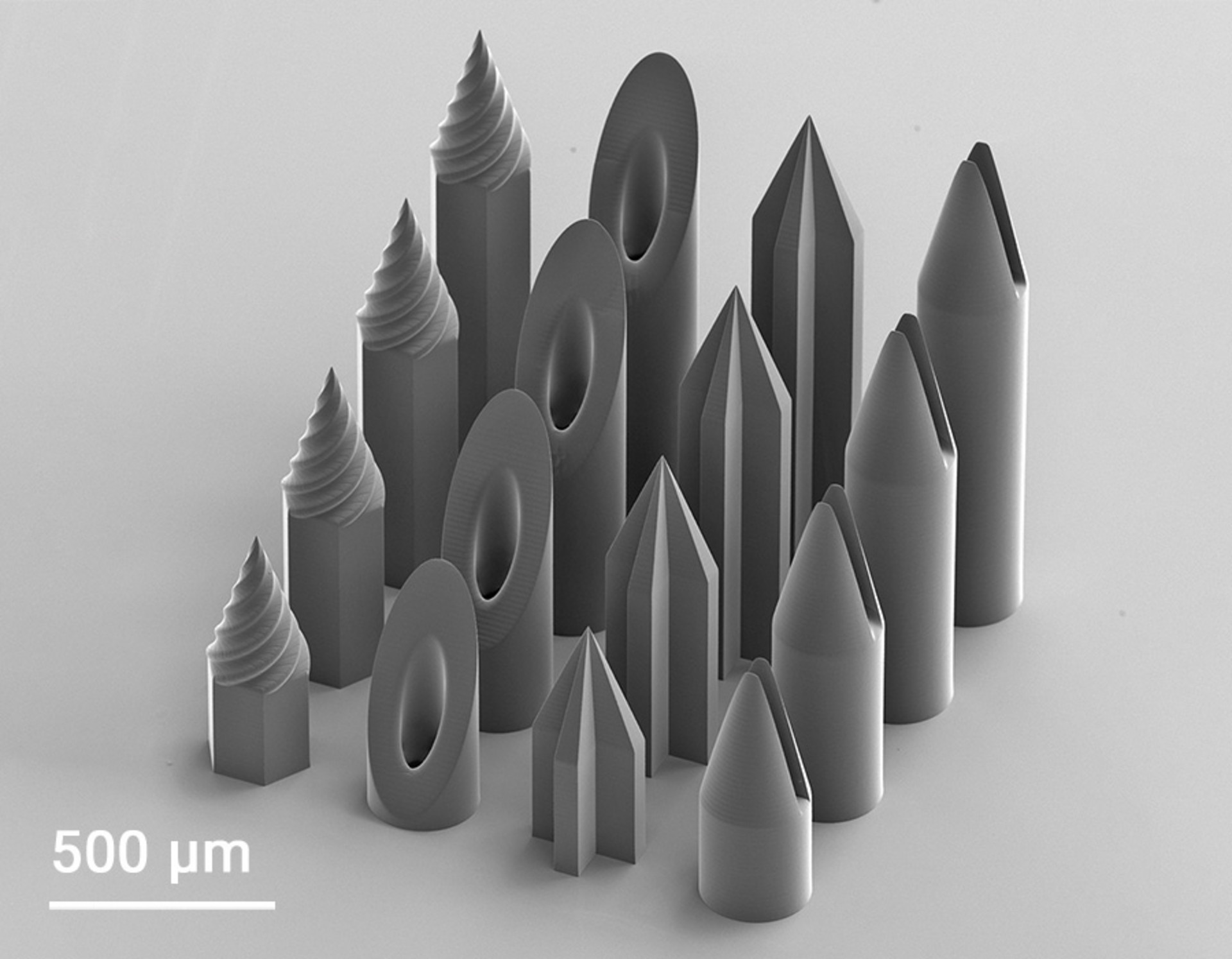

Additive manufacturing (AM) is inspiring scientists, engineers, and product designers in many areas of science and industry to create innovative designs with its fast and cost-effective approach to prototyping and manufacturing. Additive manufacturing (AM) approaches have the advantage of allowing to produce very complex geometries and structures that would otherwise be impossible to create. However, conventional 3D printing lacks the resolution required to print features at the micrometer scale or even smaller. Two-photon lithography unlocks the power of high-resolution 3D printing for nanofabrication and microfabrication tasks.

3D printing with submicron features

The smallest feature sizes achieved by 2-photon polymerization extend far into the submicron range, exceeding the capabilities of conventional 3D printing technologies. For example, Fused Deposition Modeling (FDM) or Selective Laser Sintering (SLS) are typically limited in their vertical and lateral resolution with feature sizes in the range of several hundred micrometers. In contrast to these methods, 2PP enables feature size control down to 100 nanometer and optical quality surfaces with a surface roughness Ra down to 5 nm. It thus offers the highest resolution 3D printing among all commercially available AM technologies.

Why is 3D microfabrication based on

Two-Photon Polymerization superior in resolution?

3D printing technologies such as high-resolution stereolithography (SLA), digital light processing (DLP), and projection microstereolithography (PµSL) utilize UV light curing to crosslink liquid photopolymers. This process is primarily based on one-photon absorption, which is governed by Beer’s law. This leads to absorption and subsequent polymerization of the photoresin throughout the exposed volume, limiting resolution and precision. In contrast, Two-Photon Polymerization (2PP) is triggered by two-photon absorption, which only occurs in a limited volume at the laser focus. Absorption is proportional to the square of the local intensity, which is only high enough at the laser focus to absorb two or more photons simultaneously.

Therefore, two-photon lithography enables the curing of 3D structures with much greater precision than 3D printing based on one-photon absorption. This allows for the creation of complex structures, ranging from 2.5D microoptical structures all the way to virtually any 3D structures, with excellent shape accuracy.

Enhanced 3D printing capabilities

with Dip-in Laser Lithography (DiLL)

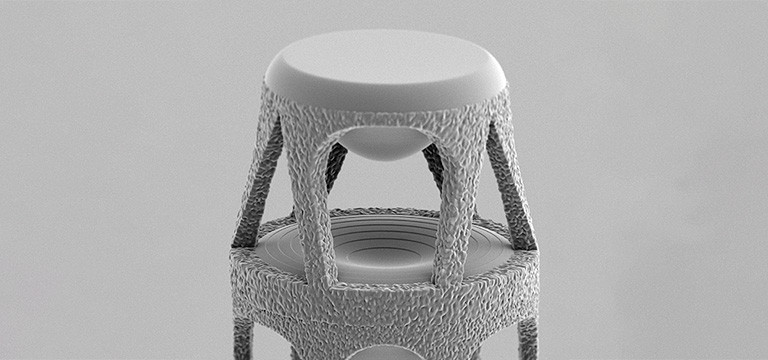

Nanoscribe’s proprietary Dip-in Laser Lithography (DiLL) enhances 2-photon polymerization by dipping an objective lens directly into the liquid photoresin for an aberration-constant printing. Thus the photoresin also serves as an optical immersion medium. The refractive index matching between the focusing optics and the print material ensures ideal, aberration-free focusing for the highest resolution in 2PP-based 3D printing. Furthermore, the writing laser is not focused through the substrate (e.g. oil immersion configuration), but writes the print object directly onto the substrate. As a result, the working distance of the focusing optics does not limit the height of the 3D printed object, which is especially beneficial for printing high and high aspect ratio objects.

The invention of DiLL makes it possible to produce high structures with excellent shape accuracy and quality. It is therefore the standard printing configuration for convenient operation in the redesigned upright platform of the Quantum X systems.

Design freedom across four scales

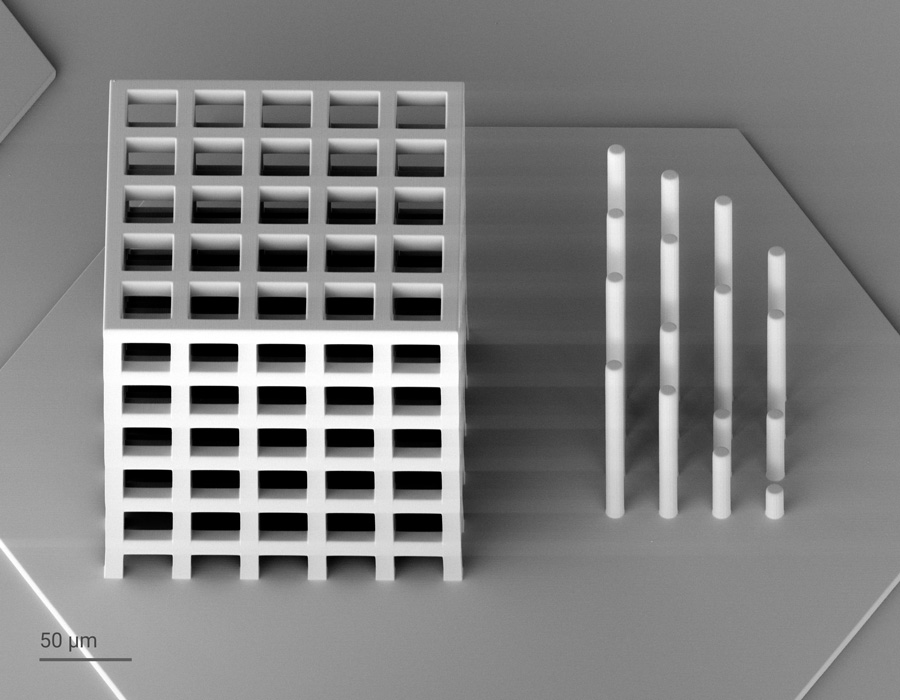

The Nanoscribe 2PP systems for 3D nano- and microfabrication provide exceptional versatility, precision, and speed, covering multiple applications at four scales: nano, micro, meso, and macro. The corresponding Print Sets, which include a print head with an objective lens, appropriate photoresin, and optimized print parameter presets containing slicing, hatching, laser power and galvo settings, are designed to meet different needs from the nanometer to the centimeter scale:

- Nanoscale printing with feature size control down to 100 nanometers

- Microscale printing with submicron features and structure dimensions up to 700 micrometers

- Mesoscale printing speeds batch production of high-precision parts up to a few millimeters in size

- Macroscale printing accelerates batch production of centimeter-sized high-precision parts up to 30 cubic centimeters

Wide range of materials

for 2.5D and 3D nano- and microfabrication

The Nanoscribe microfabrication systems are designed as open material systems that can be used with a wide range of materials to enable a variety of applications. Nanoscribe IP and IPX resins are polymer printing materials specifically designed for rapid 2.5D and 3D nano- and microfabrication, providing excellent shape accuracy and mechanical stability. To meet the requirements of material development and functionalization, various third-party and customized materials can be utilized, such as biocompatible acrylates, biomaterials, and bioresins. Materials such as hyaluronic acid, PEGDA-based hydrogels, GelMA-based hydrogels and other hydrogel blends are available from our partners Advanced BioMatrix, CELLINK and BIO INX.